Freund 90mm Trimmer Head

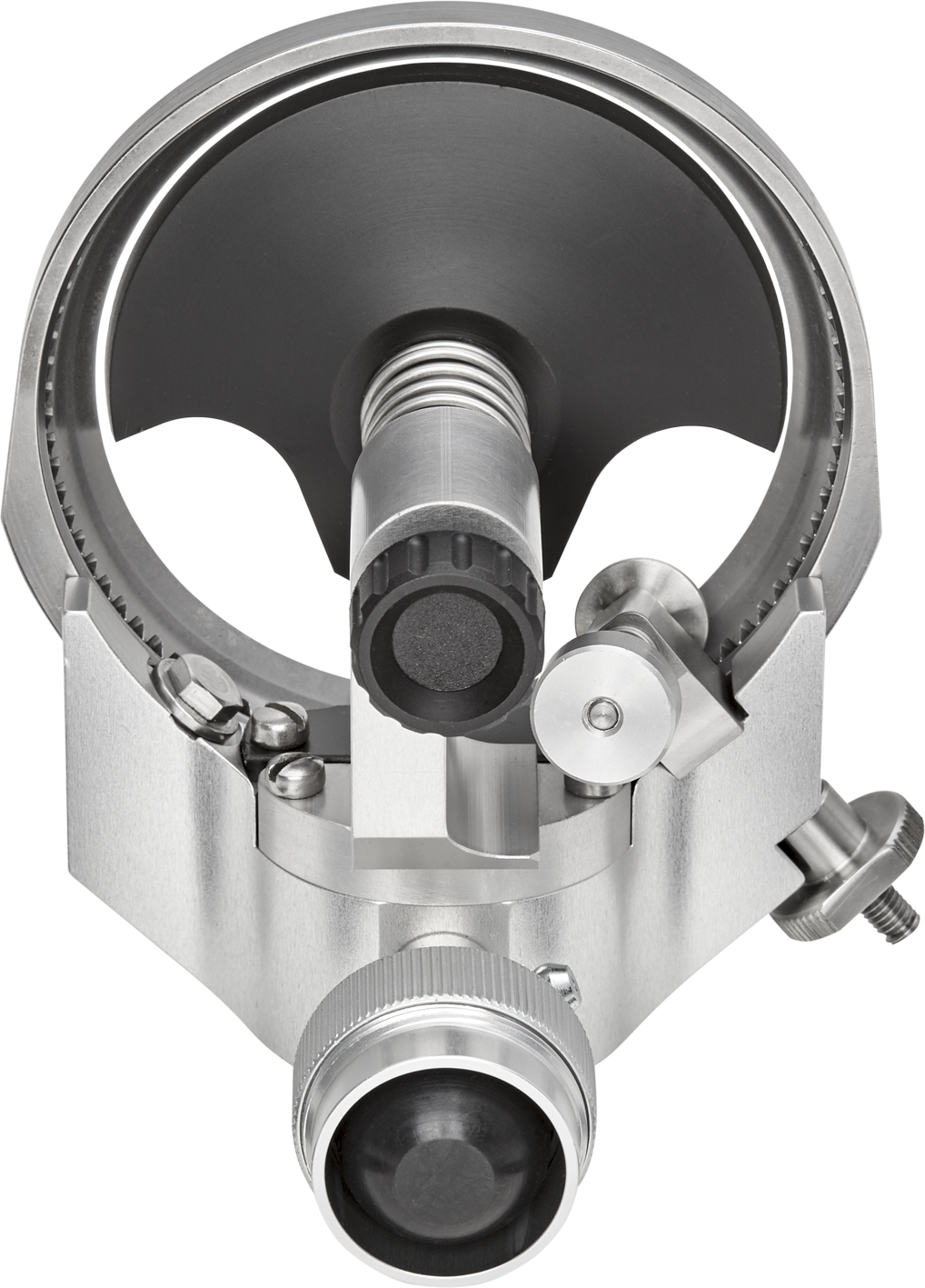

- Stainless Steel Depth control

Quality Trimmers from Freund

Choice of electrical or pneumatic power

Further improvements to the surface of the trimmer blade

Shorter downtimes and lower maintenance costs thanks to low-wear quality of components

Ergonomic handles in a robust, abrasion-free plastic design

Patented quick-change blade system for changing the trimming blade without using tools

Significant improvement in user safety through optional start-stop safety system

Quiet running minimises vibrations in the handpiece

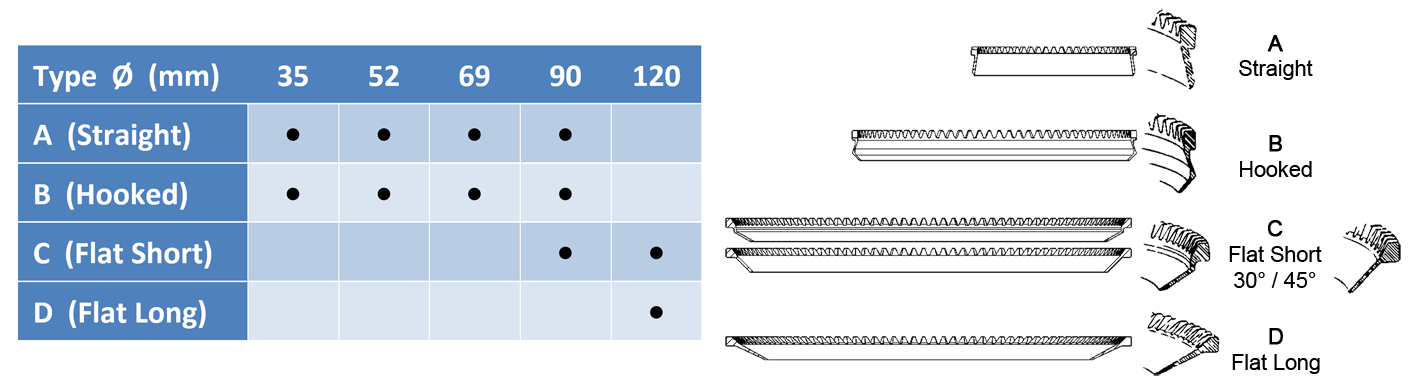

Four different blade types A, B, C and D with diameters of 35, 52, 69, 90 and 128mm

Also available with cutting depth control system in a robust, hygienic stainless steel design as an option

Application Examples for Ø 90mm Blade

|

Deboning / Cleaning: |

Removal: |

Removal of Fat / Trimming: |

Slicing: |

|

Heads (A) |

Cheeks (A) |

Skins (C) |

Gyros / Kebab (C) |

|

Chicken Breast (B) |

Warm Fat Removal (C) |

||

|

Remains of Skin (C) |

Hard Fat Removal (B) |

||

|

Pork Fillet (A) |

Ham / Shoulder / Cutlet (B/C) |

||

|

Tuna (C) |

|

Models Available |

|

|

|

|

|

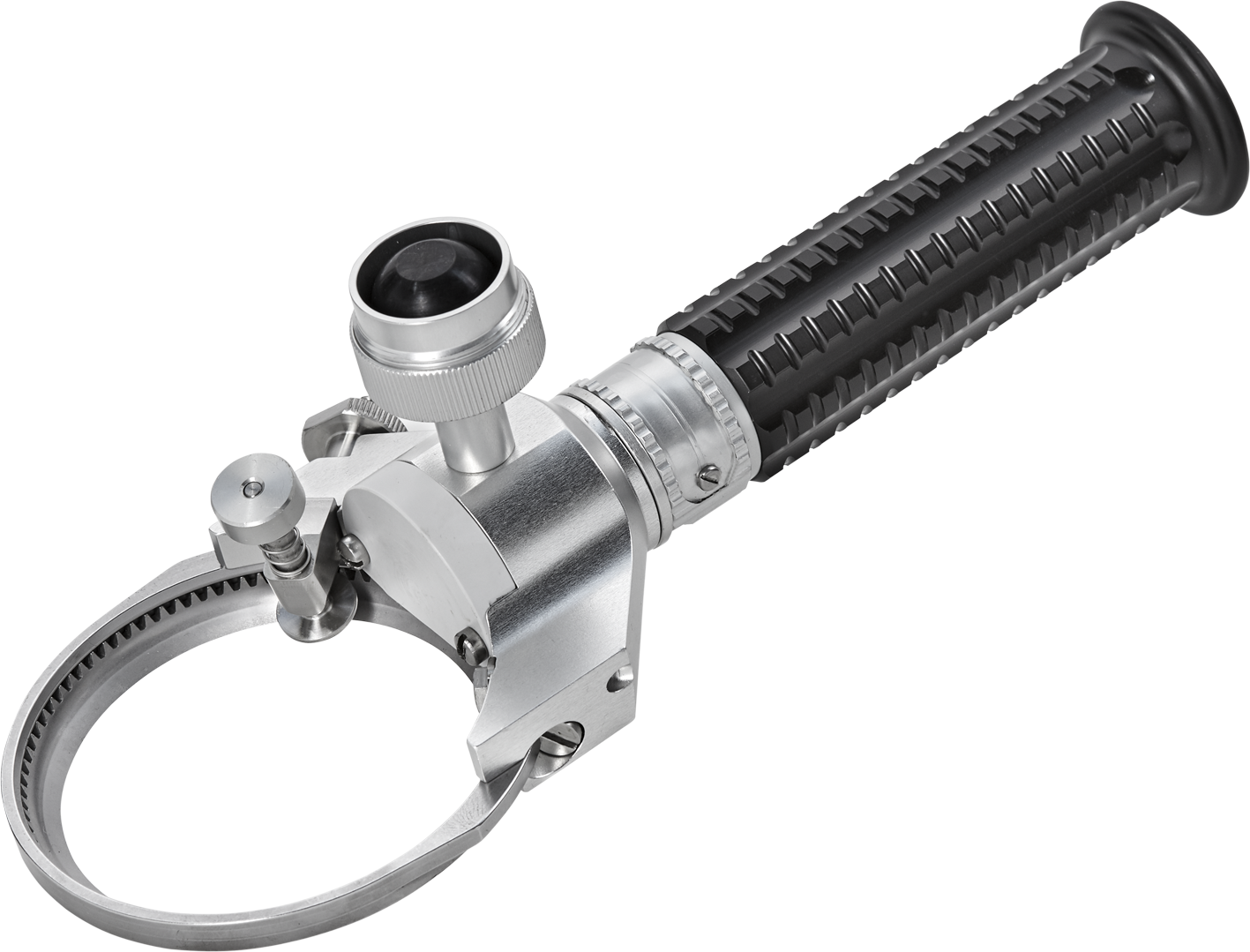

928-020-E90 Electric Motor |

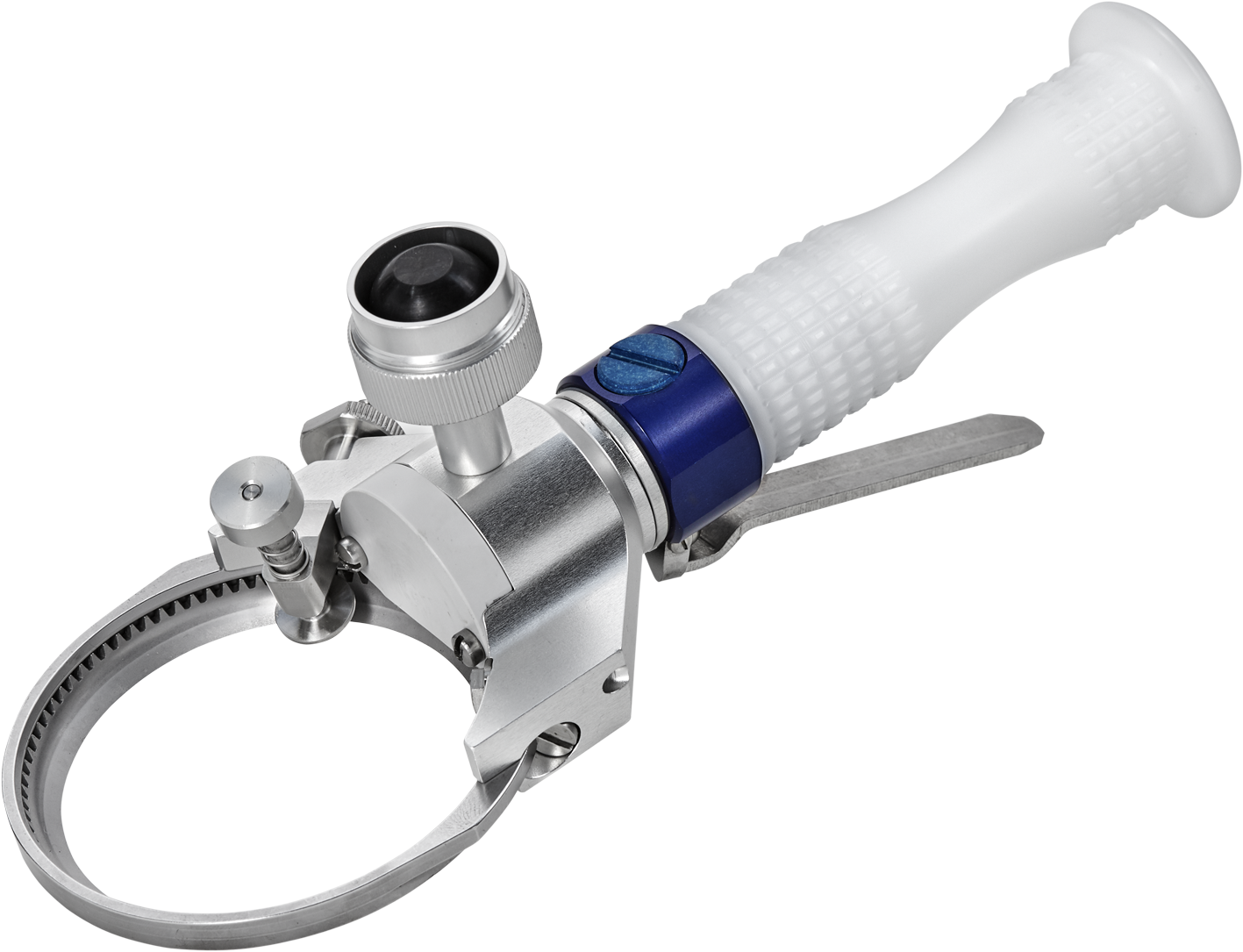

928-020-EF90 Electric Motor with On/Off safety system Includes stop lever on hand piece |

|

|

|

|

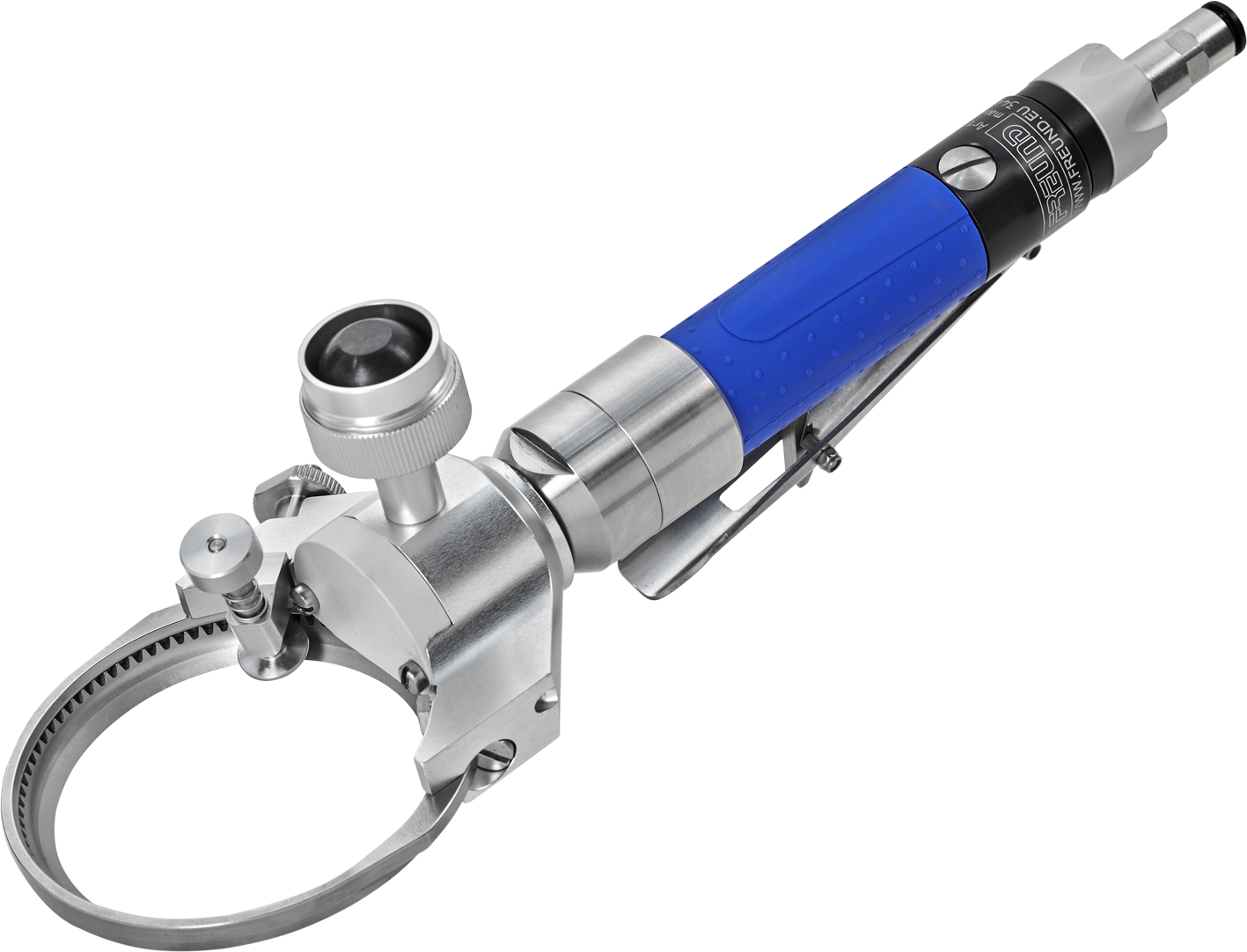

982-020-P90 Pneumatic Motor |

928-020-PL90 Pneumatic Motor with Large Grip |

Ring Blade Selection

Your Cost Effective Solution

In modern meat processing, the quality of the end product is determined to a significant extent by the quality and efficiency of the machines used. The requirements of modern meat processing are high. Heavy strain on trimmers means that maintenance related downtimes are common and high maintenance costs can be incurred. The challenge is therefore to create a tool that is efficient, maximises the quality of the end product, and is both hard-waring and cost-efficient. That's precisely where FREUND comes into its own. With our current series 2 trimmers, we have created products which use tried and tested components and high-quality materials to provide a low-maintenance and therefore cost-saving alternative to other trimmers available on the market.

The right machine for every application

From low-loss removal of fat from meat, poultry and fish products through to previse cutting of wafer thin slices of salmon - with our electric or pneumatic trimmers, we provide you with the right tool for the various requirements of your business. The modular design of our trimmers gives you the option to choose from four different blade types in five diameters (35mm, 52mm, 69mm, 90mm and 128mm) and from countless optional features such as an economic thumb rest, cutting depth control in a robust and hygienic stainless steel design, and many other features.

Trimmer Features:

Depth Control:

Even cutting depth (individually adjustable)

Higher yield thanks to lower number of rejects

Especially suited for degreasing hard and cold meat in variants DCF (plastic) and DC2F (stainless steel)

Thumb Rest:

Ergonomically shaped to enable fatigue-free working

Freely adjustable for right and left handers

Significant increase in user safety

Trimmer Handpieces:

Ergonomically shaped, abrasion free and hygienic

Optimal handing thanks to different handle shapes

Available in handle diameters 31, 34, and 38mm

Connecting Kits EF1 / EF2 / ADAPTIVE

Low maintenance thanks to integrated coupling sleeve

Compatible with all FREUND hand pieces

Also available as a special ADAPTIVE version to enable further use of your exiting trimmer motor*

*compatible with common trimmer motors

Options:

|

Ø (mm) |

35 |

52 |

69 |

90 |

128 |

|

A (straight) |

• |

• |

• |

• |

|

|

B (hooked) |

• |

• |

• |

• |

|

|

C (flat short) |

• |

• |

|||

|

D (flat long) |

• |

||||

|

Cutting depth control |

DCF / DCS |

DCF / DCS / DC2F |

|||

|

Pinion & bushing |

small |

small |

small |

large |

large |

|

Thumb rest |

• |

• |

• |

• |

• |

|

Grease cup |

small/large |

small/large |

small/large |

small/large |

small/large |

|

Sharpening steel |

• |

• |

|||

|

Pneumatic motor PNM2 |

• |

• |

• |

• |

• |

|

Start-stop safety system |

• |

• |

• |

• |

• |

2 year Manufacturer's Warranty:

Below are the terms of Manufacturer’s warranty offered by Mitchell Engineering Food Equipment Pty Ltd. 23 Storie Street Clontarf.

Warranty Coverage:

We guarantee that our products are free from defects in materials and workmanship under normal use for a period of 2 years from the date of your purchase

Warranty Claims Process:

- Notification: If you believe your product has a defect, please contact our customer service department at 07 3283 4536 or notify us in writing to info@mefe.com.au

- Proof of Purchase: Provide proof of purchase, invoice number or copy of tax invoice required.

- Inspection: If necessary, we may request you to return the defective product for inspection to determine the nature and cause of the defect. The cost to return the product may be at your expense.

Warranty Exclusions:

This warranty does not cover defects or damage arising from misuse, modification, neglect, normal wear and tear, or force majeure events beyond our control or failure to adhere to general maintenance as specified within the product manual.

This warranty does not apply to consumables such as batteries, ink, filters and globes.

Remedies:

If a defect covered by this warranty is properly notified to us within the warranty period, and is determined to be covered, we will, at our discretion, repair or replace the defective product.

Any defective parts/products replaced by us under this warranty will be deemed to be the property of MEFE.

Limitation of Liability:

Our liability is limited to the repair or replacement of the defective product and excludes consequential or incidental damages to the extent permitted by law.

Consumer Rights:

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

- Blade Size:

- 90mm