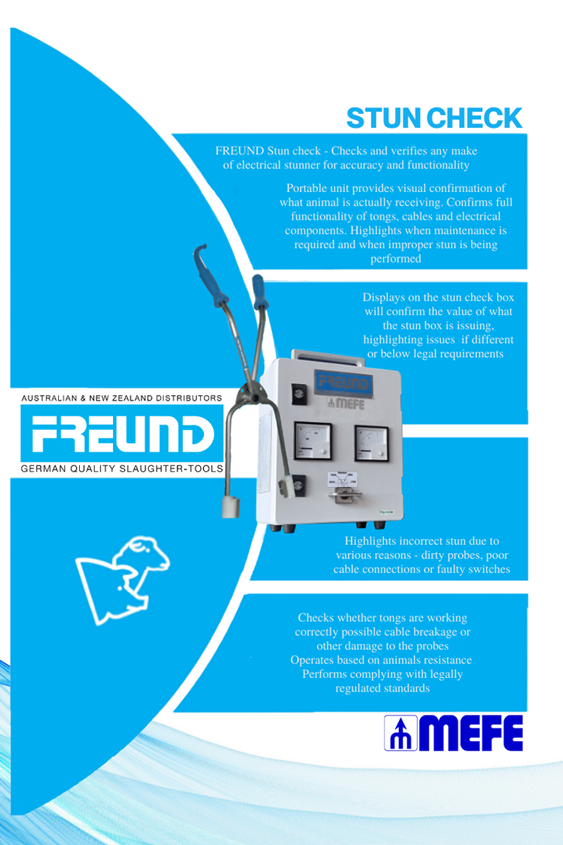

STUN CHECK

In the world of Abattoir livestock management, humane treatment and safety are paramount. Introducing the Electrical Stun Check, an exceptional testing unit designed to validate the functionality and safety of all electric stunners from any manufacturer. With its innovative technology, this unit guarantees accurate assessment and ensures compliance to animal welfare and the safety and wellbeing of operators.

Key Features and Benefits:

Visual Verification: The Electrical Stun Check offers a real-time visual display of the electric shock being delivered to the animal before actually stunning the Animal. This visual representation is cross-referenced with the expected output from the stun box, ensuring alignment between the intended and actual shock levels.

Fault Detection: This cutting-edge unit is equipped to highlight faulty stun conditions caused by dirty probes, poor cable connections, or malfunctioning switches. It empowers operators to identify and rectify issues before they lead to improper stunning.

Compliance and Standardization: The Electrical Stun Check operates in strict adherence to the standards regulated by law. It guarantees that stunning procedures are carried out in compliance with established safety guidelines, safeguarding both animals and operators.

Multi-Purpose Functionality: This versatile unit serves multiple purposes, including the functional testing of individual programs within the stunner and the evaluation of the correct operation of tongs. It detects potential cable breakages, damage to tongs, or other irregularities that might compromise the stunning process.

Ampere Visualization: Operating based on the internal resistance that mirrors the resistance across the animal's brain, the unit displays the amps received by the animal. These values must correspond accurately with the stun box's output, ensuring precision and safety.

Pre-Shift Verification: As a routine before each shift, operators stun the test box and visually confirm whether the measured values on the Electrical Stun Check match those displayed on the stunner. This step guarantees that the stunner is delivering the intended shock levels.

Instant Issue Detection: In cases where the amps received by the tester fall below the output of the stunner, the unit instantly identifies issues such as dirty electrodes, frayed wires, or broken connections in the tongs. This immediate detection prevents improper stunning and ensures animal welfare.

User-Friendly Interface: Operating the Electrical Stun Check is effortless with a simple rotary switch that selects the appropriate resistance level (1, 2, or 3) to replicate the animal being stunned, from small lambs to large boars. The unit is completely portable and has no cables or power requirements.

Variable Test Objectives:

The Electrical Stun Check features four variable test objectives based on resistivity:

123.5 Ohms: Suitable for sheep, goats, and piglets.

173.5 Ohms: Designed for smaller pigs and sows.

1200 Ohms: Tailored for larger pigs and boars.

1710 Ohms: Ensures human safety by detecting if the stunner functions on a person. Stunner must not work at this setting.

Choose the Electrical Stun Check for unmatched accuracy, enhanced safety, and exceptional livestock management. Join the ranks of operators who prioritize precision and animal welfare with every stunning procedure.

Weight: 6.8 (Kg), H: 370(mm), W:265(mm), Depth: 200(mm)

2 year Manufacturer's Warranty:

Below are the terms of Manufacturer’s warranty offered by Mitchell Engineering Food Equipment Pty Ltd. 23 Storie Street Clontarf.

Warranty Coverage:

We guarantee that our products are free from defects in materials and workmanship under normal use for a period of 2 years from the date of your purchase

Warranty Claims Process:

- Notification: If you believe your product has a defect, please contact our customer service department at 07 3283 4536 or notify us in writing to info@mefe.com.au

- Proof of Purchase: Provide proof of purchase, invoice number or copy of tax invoice required.

- Inspection: If necessary, we may request you to return the defective product for inspection to determine the nature and cause of the defect. The cost to return the product may be at your expense.

Warranty Exclusions:

This warranty does not cover defects or damage arising from misuse, modification, neglect, normal wear and tear, or force majeure events beyond our control or failure to adhere to general maintenance as specified within the product manual.

This warranty does not apply to consumables such as batteries, ink, filters and globes.

Remedies:

If a defect covered by this warranty is properly notified to us within the warranty period, and is determined to be covered, we will, at our discretion, repair or replace the defective product.

Any defective parts/products replaced by us under this warranty will be deemed to be the property of MEFE.

Limitation of Liability:

Our liability is limited to the repair or replacement of the defective product and excludes consequential or incidental damages to the extent permitted by law.

Consumer Rights:

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.